Customizing mens denim overalls involves a structured, collaborative process that balances your design preferences, fit requirements, and practical needs (e.g., workwear durability vs. fashion aesthetics). Below is a step-by-step breakdown of the end-to-end workflow, from initial concept to final delivery:

1. Initial Consultation & Requirement Gathering

This phase ensures the custom product aligns with your vision. Key steps here include:

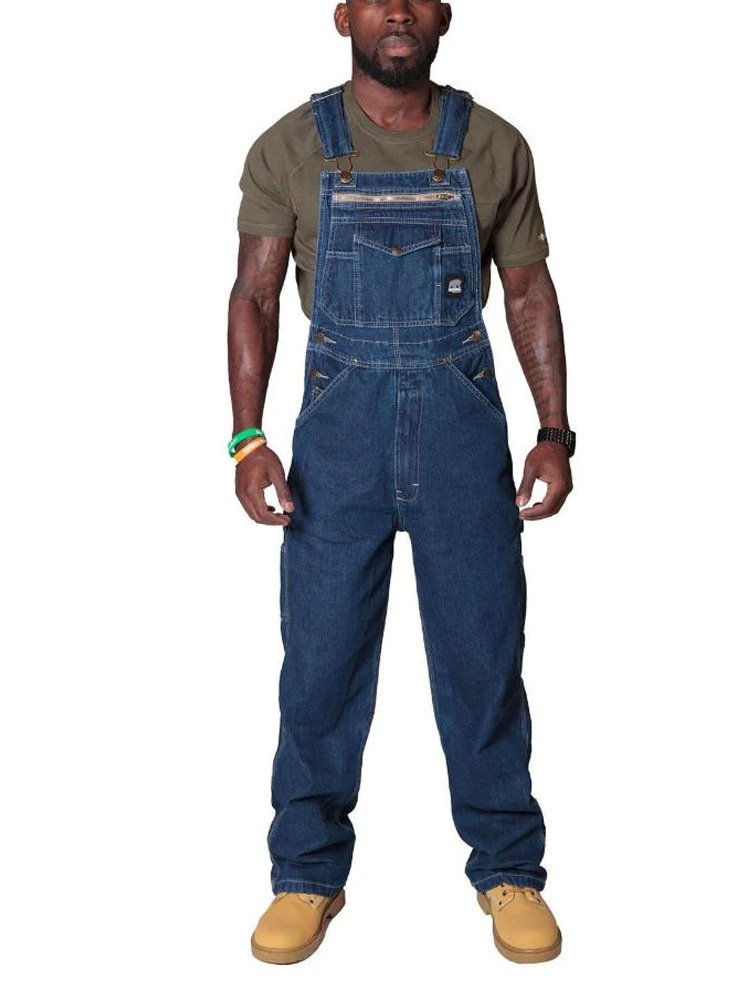

- Define core goals: Clarify the overalls’ purpose (e.g., heavy-duty workwear, casual fashion, vintage-inspired), desired style (classic straight-leg, slim-fit, cargo-style with extra pockets), and fit (relaxed, regular, tapered).

- Share design references: Provide images, sketches, or examples of overalls you like (e.g., “Levi’s 501-inspired straps” or “carpenter-style tool pockets”) to communicate details like:

- Strap design (adjustable, fixed-length, padded for comfort).

- Pocket placement (chest pockets, hip pockets, hammer loops, knee reinforcement patches).

- Hardware (brass buttons, YKK zippers, D-rings for tools, snap closures).

- Measurements & fit preferences: For a true custom fit, provide body measurements (or schedule a fitting if working with a local tailor):

- Chest, waist, hip, inseam, outseam, thigh circumference, shoulder-to-waist length (for straps).

- Note fit adjustments (e.g., “roomier thighs for mobility” or “slimmer calves for a modern look”).

2. Design Finalization & Technical Specification (Tech Pack)

Once requirements are clear, the manufacturer/designer translates your ideas into a technical pack (tech pack)—a detailed document that guides production. The tech pack includes:

- 2D/3D sketches of the overalls (front, back, side views).

- Exact measurements (e.g., “strap width: 4cm,” “knee patch size: 15x20cm”).

- Fabric details (denim weight, composition, wash type—see Step 3).

- Stitching specifications (e.g., “flat-felled seams for durability,” “topstitch color: indigo”).

- Hardware details (e.g., “brass shank buttons,” “black YKK zipper”).

- Finishings (e.g., “distressed knee rips,” “stone wash with slight fading”).

You’ll review and approve the tech pack to avoid miscommunication later.

3. Denim & Material Selection

Denim is the backbone of overalls—its weight, composition, and wash directly impact comfort, durability, and style. Key choices here:

- Denim weight (oz):

- 10–12 oz: Lightweight, soft, ideal for casual wear (breathable for warmer weather).

- 14–16 oz: Medium-weight, balanced durability/comfort (versatile for everyday or light work).

- 18–20 oz: Heavyweight, rugged, designed for heavy workwear (e.g., construction, farming—resistant to tears).

- Denim composition:

- 100% cotton: Classic, stiff initially (softens with wear), minimal stretch (authentic vintage feel).

- Cotton + elastane (2–5%): Stretch denim, offers better mobility (great for slim-fit or all-day wear).

- Denim wash:

- Raw/unsanforized: Unwashed, deep indigo color (will shrink 3–5% after first wash—pre-wash if you want to avoid this).

- Sanforized: Pre-washed to minimize shrinkage (ready-to-wear).

- Washed finishes: Stone wash (soft, faded), enzyme wash (gentler fading), distressed (rips, frays, whiskering—fashion-focused).

- Hardware & trims:

- Buttons/rivets: Brass (classic, ages well) or stainless steel (rust-resistant for workwear).

- Straps: Denim (matching or contrasting) or webbing (for heavy-duty work).

- Thread: Polyester-cotton blend (strong, colorfast—matches or contrasts with denim).

4. Pattern Making (Custom Sizing)

Unlike ready-to-wear (which uses standard sizes), custom overalls require a one-of-a-kind pattern tailored to your measurements. The process:

- The pattern maker uses your body measurements (or 3D scan, for precision) to create a 2D paper or digital pattern (using software like Gerber Accumark or Lectra Modaris).

- The pattern includes all individual pieces: front/back body panels, straps, pockets, knee patches, and waistband (if applicable).

- For workwear or functional designs, the pattern may add extra fabric at stress points (e.g., crotch, strap attachments) for durability.

5. Sample Production & Fit Testing

Before full production, a sample pair is made to test fit, design, and functionality—this is the most critical step to avoid errors.

- The manufacturer cuts the selected denim according to the custom pattern and sews a prototype.

- You (or a fit model) try on the sample to check:

- Overall fit (length, waist, thigh, strap adjustability).

- Functionality (pockets are accessible, zippers/buttons work, straps stay in place).

- Design accuracy (details like patches, distressing, or stitching match the tech pack).

- Feedback is collected: Adjustments (e.g., “shorten inseam by 2cm,” “widen chest pockets”) are made to the pattern, and a revised sample may be produced until you approve the fit and design.

6. Bulk Production (for Multiple Units) or Single-Unit Manufacturing

Once the sample is approved, production begins (scale depends on whether you need 1 custom pair or 100+):

A. Cutting

- The denim fabric is laid flat (with attention to the grain line—critical for avoiding distortion) and marked with the pattern.

- For consistency, computerized cutting machines (CNC) are used to cut all pieces (body, pockets, straps) with precision.

- If the denim is raw/unwashed, some manufacturers pre-wash it first to prevent shrinkage post-production.

B. Sewing & Assembly

- Seamstresses follow the tech pack to sew the overalls step-by-step:

- Attach straps to the back body panel.

- Sew front and back body panels together (using flat-felled seams for strength—common in denim).

- Add pockets (chest, hip, tool loops) and reinforce stress points (e.g., rivets at pocket corners).

- Insert zippers/buttons and attach waist adjusters (if needed).

- Add knee patches (for workwear) and topstitch details (for style and durability).

C. Washing & Finishing

- The sewn overalls undergo the agreed-upon wash process (stone wash, enzyme wash, distressing) to achieve the desired look and softness.

- After washing, overalls are dried, pressed (to set the shape), and trimmed (loose threads removed).

- Custom labels (brand label, care label, size label) are attached, along with any embroidery or patches (e.g., a work logo).

7. Quality Control (QC)

Strict QC ensures the final product meets your standards. Inspectors check:

- Fit: Verify measurements match the approved sample (no inconsistencies).

- Construction: Stitches are even and secure (no loose threads), hardware functions (buttons don’t fall off, zippers glide), and seams are reinforced.

- Fabric & Finish: No fabric defects (holes, uneven dye), wash consistency (fading/distressing matches the sample), and no color bleeding.

- Details: All custom elements (pockets, patches, embroidery) are correctly placed.

8. Packaging & Delivery

- The finished overalls are folded or hung (to avoid wrinkles) and packaged with care instructions (e.g., “wash cold, hang dry to preserve fade”).

- For international orders, packaging may include moisture-resistant materials to protect denim during shipping.

- Delivery timelines vary: A single custom pair takes 2–4 weeks (from consultation to delivery), while bulk orders (50+) may take 4–8 weeks.

Key Tips for a Successful Custom Order

- Be specific: Vague requests (e.g., “make it cool”) lead to misalignment—share photos, measurements, and fabric swatches if possible.

- Test the sample: Never skip the fit test—even small adjustments (e.g., strap length) make a big difference in comfort.

- Choose a reputable manufacturer: Look for brands/tailors with experience in denim workwear (they understand durability needs) or fashion (for trendy details).

By following these steps, you’ll get a pair of men’s denim overalls that fits perfectly, matches your style, and meets your practical needs.